PRODUCT OVERVIEWS

The 20kV power transformer is suitable for power supply applications in power grids, rural grids, and other fields, which delivers exceptional overload capacity and short-circuit resilience. It ensures stable operation under complex conditions while meeting modern power systems' demands for compact and efficient equipment.

Performance Features

High Temperature Resistance

Nomex® paper insulation system, providing better high-temperature resistance and enhanced safety, with an excellent cooling system.

Low Loss

The robot’s slanted joint structure effectively reduces the transformer's no-load loss and no-load current.

Low Noise

Low magnetic flux density design, high-quality high-permeability silicon steel sheets, a Swiss fully automatic lamination machine to control lamination precision, reliable clamping and tensioning measures, and special shock absorption measures help reduce noise.

Manufacturing Process

Seven-Stage Thermal Management Technology

Insulation thermal control, fluid circuit thermal control, overload thermal control, core thermal control, sealing thermal control, component thermal control, and short-circuit thermal control.

High-Temperature Hybrid Insulation System

Temperature field analysis software determines coil hotspot distribution, enabling optimal selection of insulation materials with varying temperature ratings. This ensures all components of the transformer's insulation system achieve a service life exceeding 30 years.

Fully Automatic Stacking

The robot automatically laminates, using a fully slanted 45-degree 7-level step joint structure, which improves the lamination efficiency and quality of the transformer laminations.

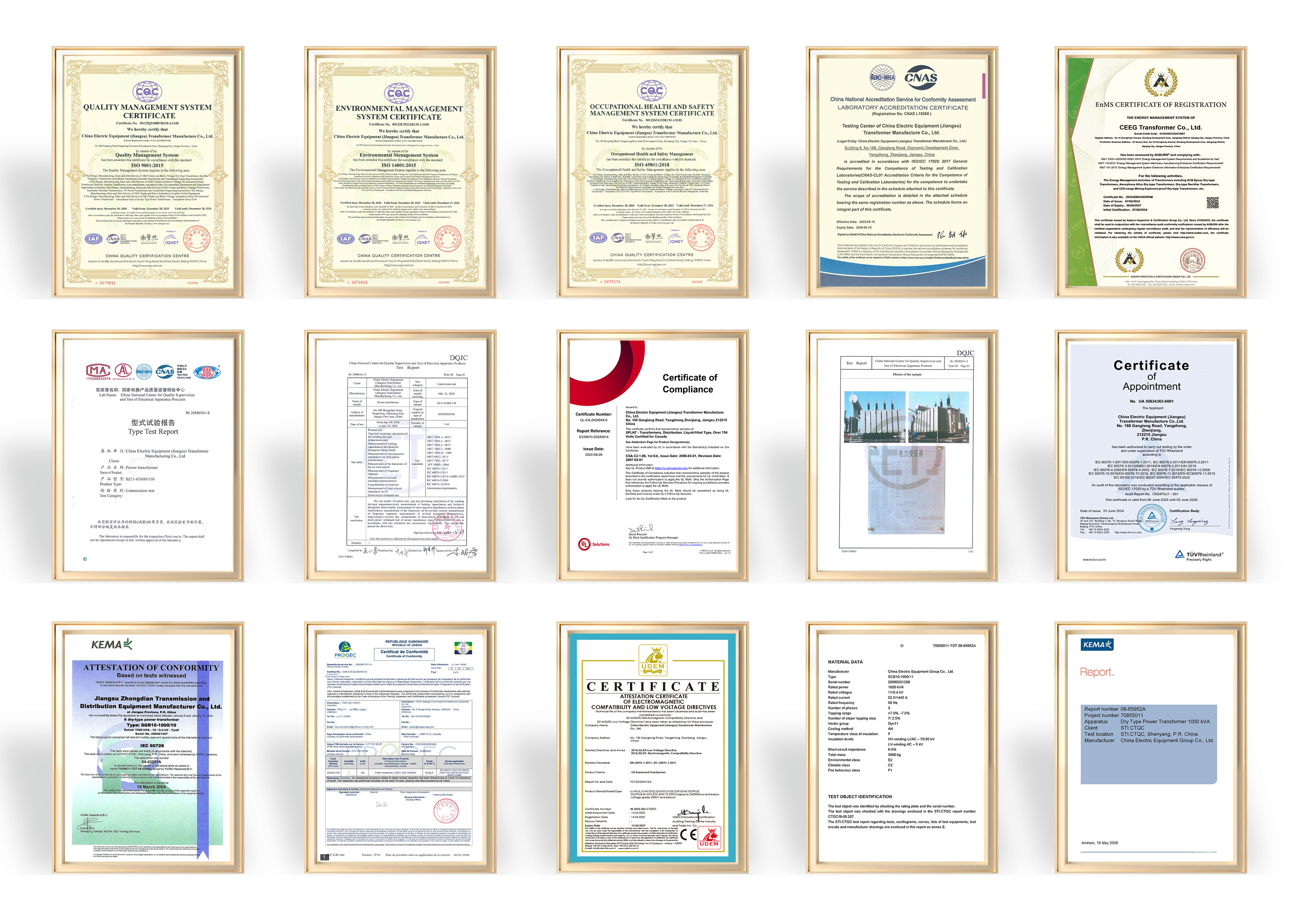

Testing and Inspection Technology.

Testing & Inspection

The company operates 2 CNAS-accredited laboratories and 1 TÜV Rheinland witnessed testing lab. All products undergo rigorous testing according to relevant standards and customized client requirements before shipment.

.png)

PARAMETERS

%20Co.,%20Ltd.%20Project.png)

.png)

.png)

.png)