PRODUCT OVERVIEWS

The 220kV oil-immersed power transformer is safe with no partial discharge, and features high efficiency and energy conservation. It is widely applied in key fields such as the State Grid, large industrial enterprises, and energy power stations, providing solid and reliable power support for urban power supply, industrial production, energy transmission, etc.

Performance Features

High overload capacity

The maximum overload capacity can reach 200%, effectively enhancing the transformer's emergency overload capacity. It is suitable for distribution networks and other places with high load rates under high temperatures.

Maximizing material performance

Combined with finite element analysis of temperature fields, the insulating materials can maintain good performance under different temperature conditions, extending the service life of the transformer.

Low loss and low noise

The no-load loss is 20% lower than the national standard, and the load loss is 5% lower than the national standard. Unique noise reduction measures are adopted for different components, resulting in noise levels 3-5 decibels lower than the national standard.

Adaptability to complex environments

It can ensure the stable operation of the transformer in high temperature, high humidity, or other harsh environments, expanding the application range of the transformer.

Manufacturing Process

Seven-level temperature control technology

Insulation temperature control technology, liquid flow circuit temperature control technology, overload temperature control technology, iron core temperature control technology, sealing temperature control technology, component temperature control technology, and short-circuit temperature control technology.

High-temperature resistant hybrid insulation system

Using temperature field analysis software to determine the temperature distribution of coil hot spots, and reasonably selecting insulating materials with different temperature resistance levels, so that the service life of each component in the overall insulation system of the transformer exceeds 30 years.

Fully automatic lamination

Robot-based automatic lamination, adopting a full 45-degree inclined 7-level stepped joint structure, improves the efficiency and quality of transformer lamination.

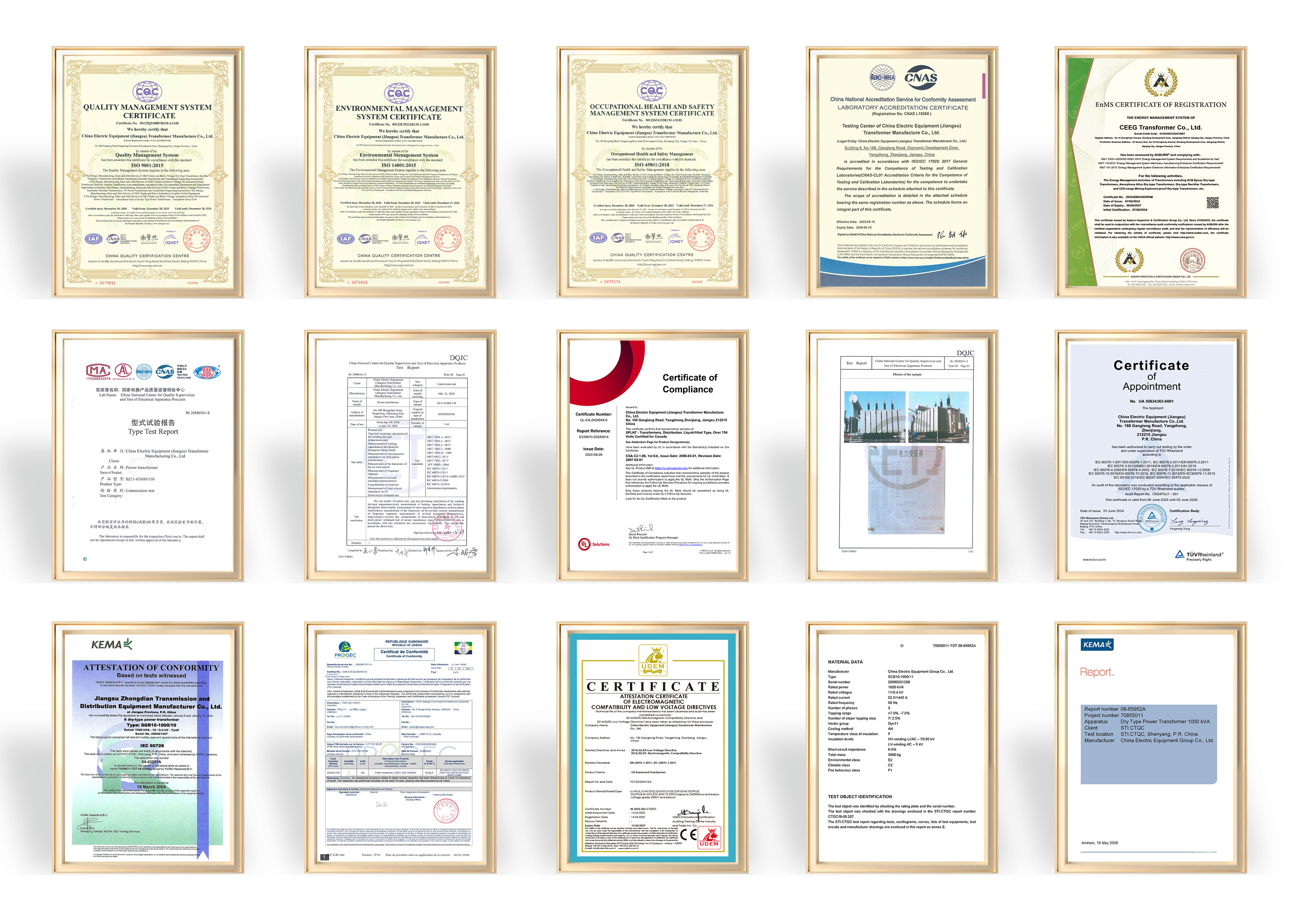

Testing and detection technology

The company has 2 CNAS laboratories and 1 TÜV Rheinland witness laboratory. All products undergo rigorous testing and inspection against relevant standards and customer-specific requirements before being shipped from the factory.

.png)

PARAMETERS

%20Gaomi%20Centralized%20Shared%20Energy%20Storage%20Project%E2%80%8B.png)

.png)

.png)

.png)