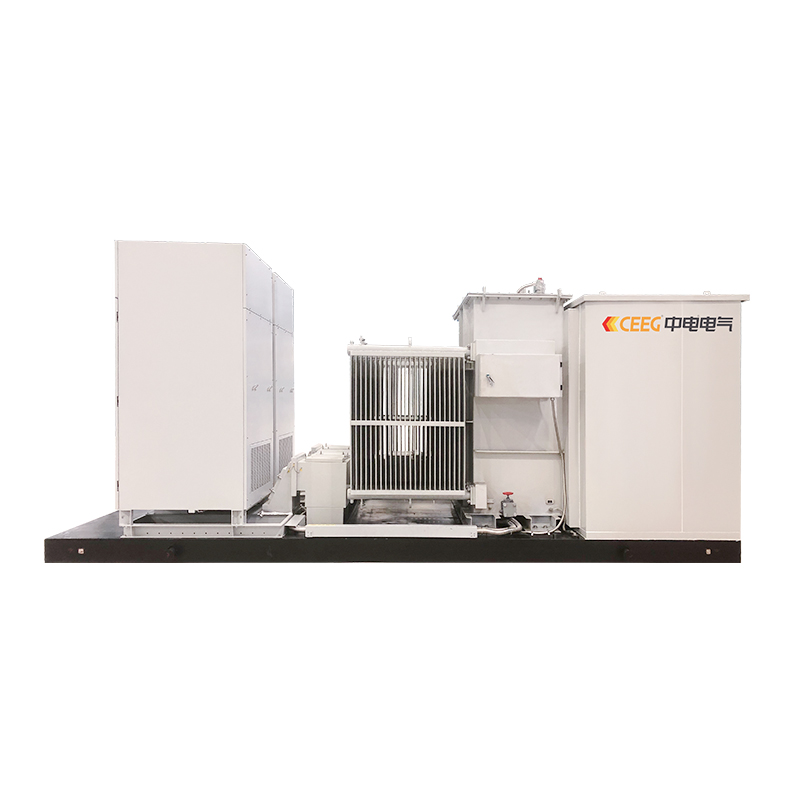

PRODUCT OVERVIEWS

The S-series 35kV power transformers have been successfully applied in the metro systems of cities such as Nanjing, Guangzhou, Chongqing, and Wuxi, providing solid power support for the rail transit industry and contributing to the pulse of the city.

Performance Features

Low Loss

The core uses high-quality, high-conductivity, cold-rolled silicon steel sheets. It is equipped with a Swiss fully automatic core stacking machine, multi-stage fully automatic stacking with fully inclined joints. The core binding employs integrated pressing and PET strap binding processes, effectively reducing the transformer’s no-load losses and no-load current.

Low Noise

The company adopts a low magnetic flux density design, high-quality high-permeability silicon steel sheets, Swiss fully automatic stacking machines for precise stacking, reliable clamping and tensioning measures, as well as special damping measures.

Leak-proof

The oil tank and oil reserve cabinet undergo positive and negative pressure leak testing to ensure no oil leaks occur during normal operation. The component installation uses flange groove structures, and all seals are made of high-quality, single-molding acrylic ester rubber to prevent oil seepage.

Strong Short-circuit Resistance

The transformer coils employ half-hard copper wire, while the core clamping components meet stringent safety requirements for withstanding maximum short-circuit mechanical forces. The windings are fully assembled and compressed as a single unit, ensuring both precise assembly integrity and proven short-circuit withstand capability.

Manufacturing Process

Seven-Stage Thermal Management Technology

Insulation thermal control, fluid circuit thermal control, overload thermal control, core thermal control, sealing thermal control, component thermal control, and short-circuit thermal control.

High-Temperature Hybrid Insulation System

Temperature field analysis software determines coil hotspot distribution, enabling optimal selection of insulation materials with varying temperature ratings. This ensures all components of the transformer's insulation system achieve a service life exceeding 30 years.

Fully Automatic Stacking

The robot automatically laminates, using a fully slanted 45-degree 7-level step joint structure, which improves the lamination efficiency and quality of the transformer laminations.

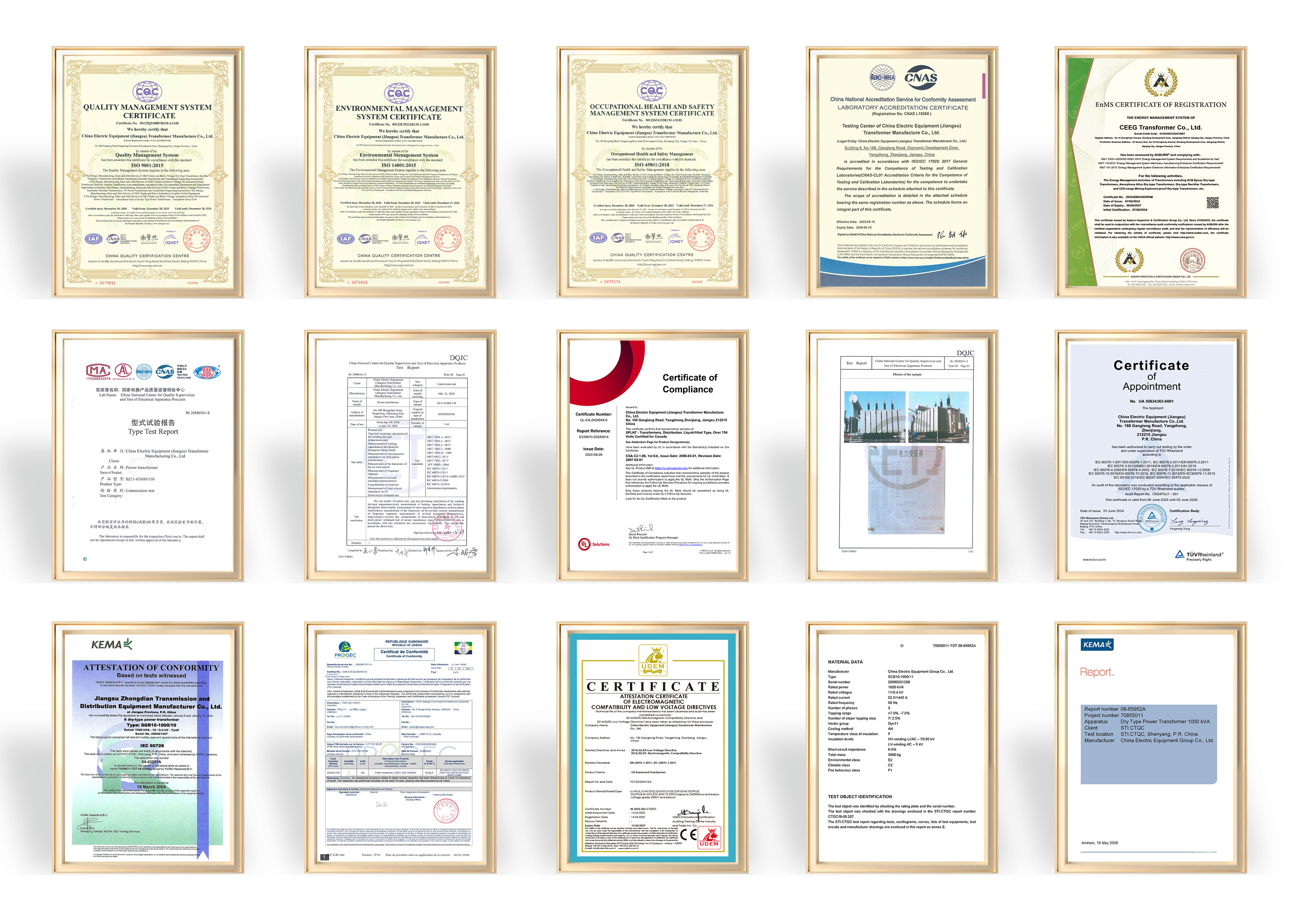

Testing and Inspection Technology

Testing & Inspection

The company operates 2 CNAS-accredited laboratories and 1 TÜV Rheinland witnessed testing lab. All products undergo rigorous testing according to relevant standards and customized client requirements before shipment.

.png)

PARAMETERS

%20Co.,%20Ltd.%20Project.png)

.png)