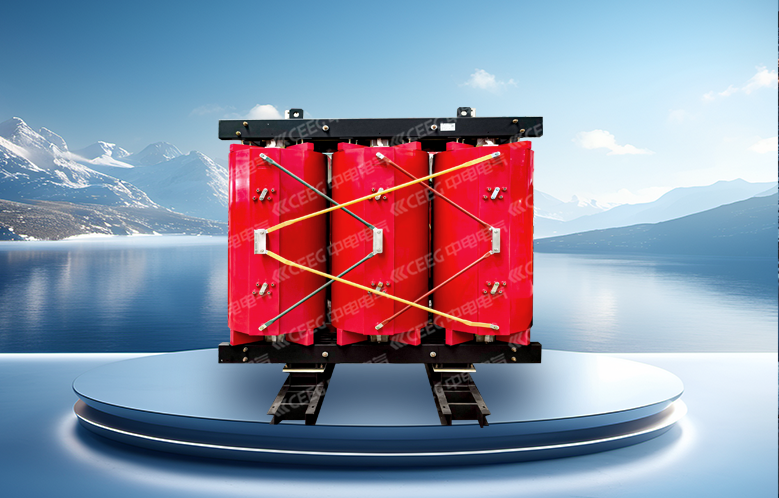

Recently, CEEG successfully developed its independently designed 8000 kVA epoxy cast resin dry-type 12-pulse rectifier transformer. This marks a milestone breakthrough for CEEG in the field of ultra-high-power rectifier transformers.

1. Six-Dimensional Performance for Exceptional Excellence

CEEG’s 12-Pulse Rectifier Transformer redefines industrial power equipment performance benchmarks through six core technological innovations. By deeply integrating breakthrough structural design with advanced material processes, it achieves comprehensive upgrades in electrical performance, safety protection, and energy efficiency.

① Large Capacity with Exquisite Structure

Single-unit capacity exceeds 8000 kVA, pushing manufacturing capabilities to new heights. The high-voltage multi-layer segmented structure enhances electrical performance, while vacuum epoxy resin casting with high-temperature curing ensures insulation reliability. Low-voltage copper foil winding technology significantly improves mechanical strength, achieving top-level deformation resistance.

② Electromagnetic Optimization with Safety Barrier

The high/low voltage axial split arrangement optimizes electromagnetic ampere-turn distribution, significantly improves short-circuit resistance, and increases fault protection response speed to milliseconds.

③ Exceptional Energy Efficiency – A Model of Energy Saving

Secondary winding output voltage difference <0.2%, reducing circulating currents between secondary windings and improving output power efficiency. No-load losses are low, achieving efficiency above 99.2%, in line with national energy-saving and emission-reduction policies, with excellent environmental performance.

④ Harmonic Purification – Guardian of the Grid

Effectively eliminates specific-order harmonics, providing excellent harmonic suppression and reducing power pollution to the grid.

⑤ Scene Adaptation – Cost Innovation

Suitable for high-power rectifier equipment, especially in scenarios requiring advanced harmonic control and power factor improvement, helping to reduce overall costs.

⑥ Safe Isolation – Dual Protection

Effectively provides electrical isolation between the rectifier and the grid, enhancing the safety of the rectifier system.

2.Core Breakthroughs Driving the Future

This cutting-edge “industrial power heart” is designed to drive critical applications. Core components are manufactured using precision vacuum casting processes, providing exceptional mechanical strength, excellent moisture and contamination resistance, and superior flame-retardant properties—fully meeting the high-end industrial equipment requirements for power purity and reliability.

It is set to become a trusted partner for high-power rectifier applications such as non-ferrous metal smelting and hydrogen production, delivering clean and efficient DC power. It injects high-quality power into high-end variable frequency drive systems such as large rolling mills and mine hoists, ensuring stable operation of core equipment; Additionally, it offers innovative, efficient, and reliable power solutions for emerging applications such as ultra-large-scale data centers and HVDC power supply.

Behind the 12-pulse rectifier transformer lies CEEG’s profound expertise in electromagnetic calculation and simulation, precision epoxy formulation and casting processes, a comprehensive ultra-high-capacity transformer testing platform, and a precise understanding of high-end industrial user needs and industry trends.

CEEG continues to drive industrial power with core technologies, constantly pushing the boundaries of innovation and empowering global customers to achieve broader success in the future!