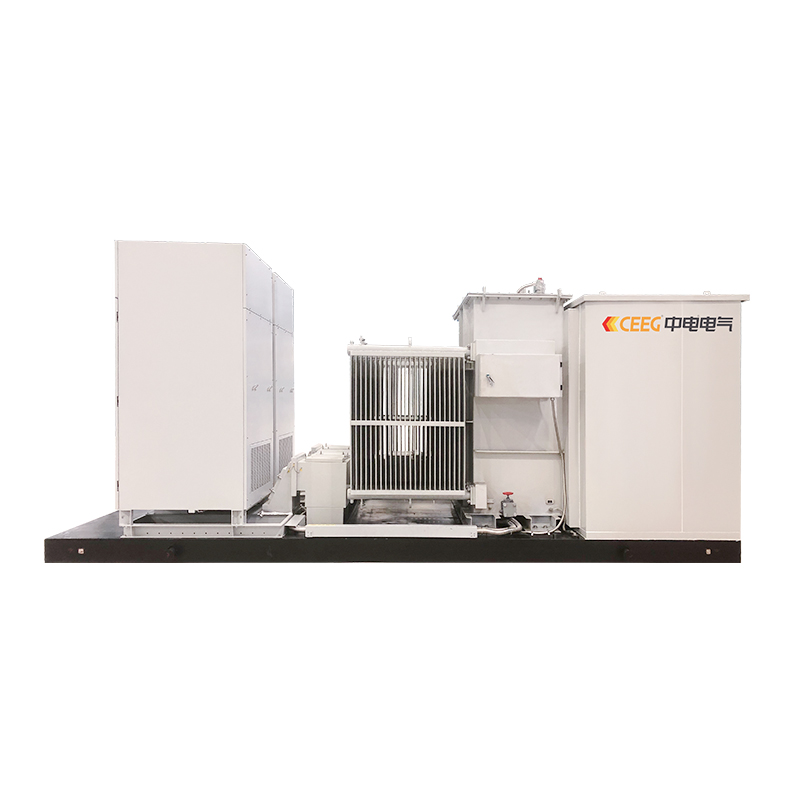

PRODUCT OVERVIEWS

CEEG's Energy Storage Dedicated Epoxy Resin Cast Dry-Type Transformer adopts advanced epoxy resin insulation technology, ensuring high efficiency and low losses, specifically engineered for the energy storage industry.

Performance Features

Heat-Resistant Insulation

Utilizes Class H (180°C) insulation materials designed for Class F temperature rise (100K). Features an ample insulation system margin and strong overload capacity.

Low Losses

No-load losses are 20% lower than international standards; load losses 10% lower. Meets national energy efficiency requirements.

Low Noise & Partial Discharge

Noise levels 10 DB below industry standards; partial discharge < 5 pC.

Flame Retardant & Fireproof

Passed F1, C2, E2 grade combustion, environmental, and thermal shock tests. Suitable for direct installation in load centers.

Manufacturing Process

3D Design

CEEG's "3D + Parametric" design software enables automated design, cost optimization, simulation, and modeling, fully considering national and industry standards to ensure product design advancement.

High Voltage Winding

High-voltage winding conductor is wound using premium conductor. Reinforced with chopped strand glass fiber mat, it is cast under vacuum using the world-class HEDRICH vacuum casting system. Partial discharge level < 5 pC.

Low Voltage Winding

Low-voltage winding uses premium strip conductor, wound on an automatic winding machine. The machine employs "wire hydraulic energy-saving tension coiling device" technology, ±0.5mm high-precision detection, and advanced argon arc welding technology.

Core

High-permeability grain-oriented silicon steel core with 45° fully mitred step-lap joints. Special anti-moisture/anti-rust coating reduces no-load loss, current, and noise.

Testing & Inspection

All products undergo strict testing per relevant standards and customer-specific requirements, including partial discharge, lightning impulse withstand, noise level, and other critical inspections.

.jpg)

PARAMETERS

.png)