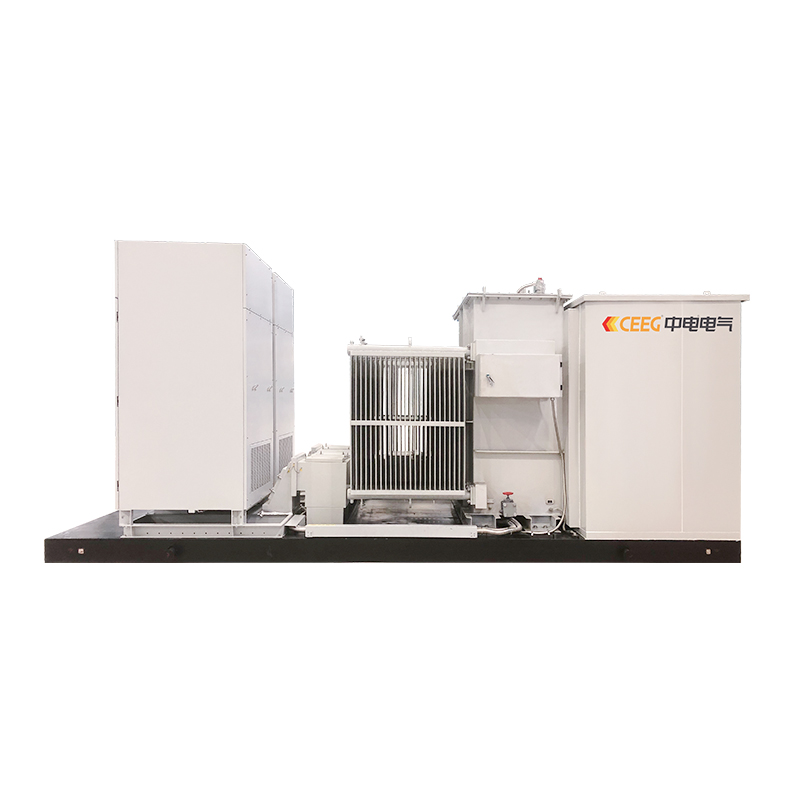

PRODUCT OVERVIEWS

The high-temperature resistant liquid-immersed traction transformer for electrified railways meets the requirements of railway departments for traction transformers, and features safety and reliability, low loss, low temperature rise, and strong overload capacity.

Performance Features

Low loss

The robot-inclined seam structure effectively reduces the transformer's no-load loss and no-load current.

Short-circuit resistance

The grid-side coil adopts a composite conductor, reinforced with short-cut glass fibers. The coil is integrally baked and cured at high temperature, with high mechanical strength and strong resistance to sudden short circuits.

Manufacturing Process

High-temperature resistant hybrid insulation system

Using temperature field analysis software to determine the temperature distribution of coil hot spots and reasonably selecting insulating materials with different temperature resistance levels, the service life of each component in the transformer's overall insulation system exceeds 30 years.

Fully automatic lamination

Robot-based automatic lamination, adopting a full 45-degree inclined 7-level stepped joint structure, improves the efficiency and quality of transformer lamination.

Oil tank

Two structures are adopted: minute (minute cover type) and barrel type. All metal parts inside and outside the tank are rounded and deburred, and the welds and seals undergo three leak detection tests (fluorescence, positive pressure, and negative pressure leak tests).

Testing and detection technology

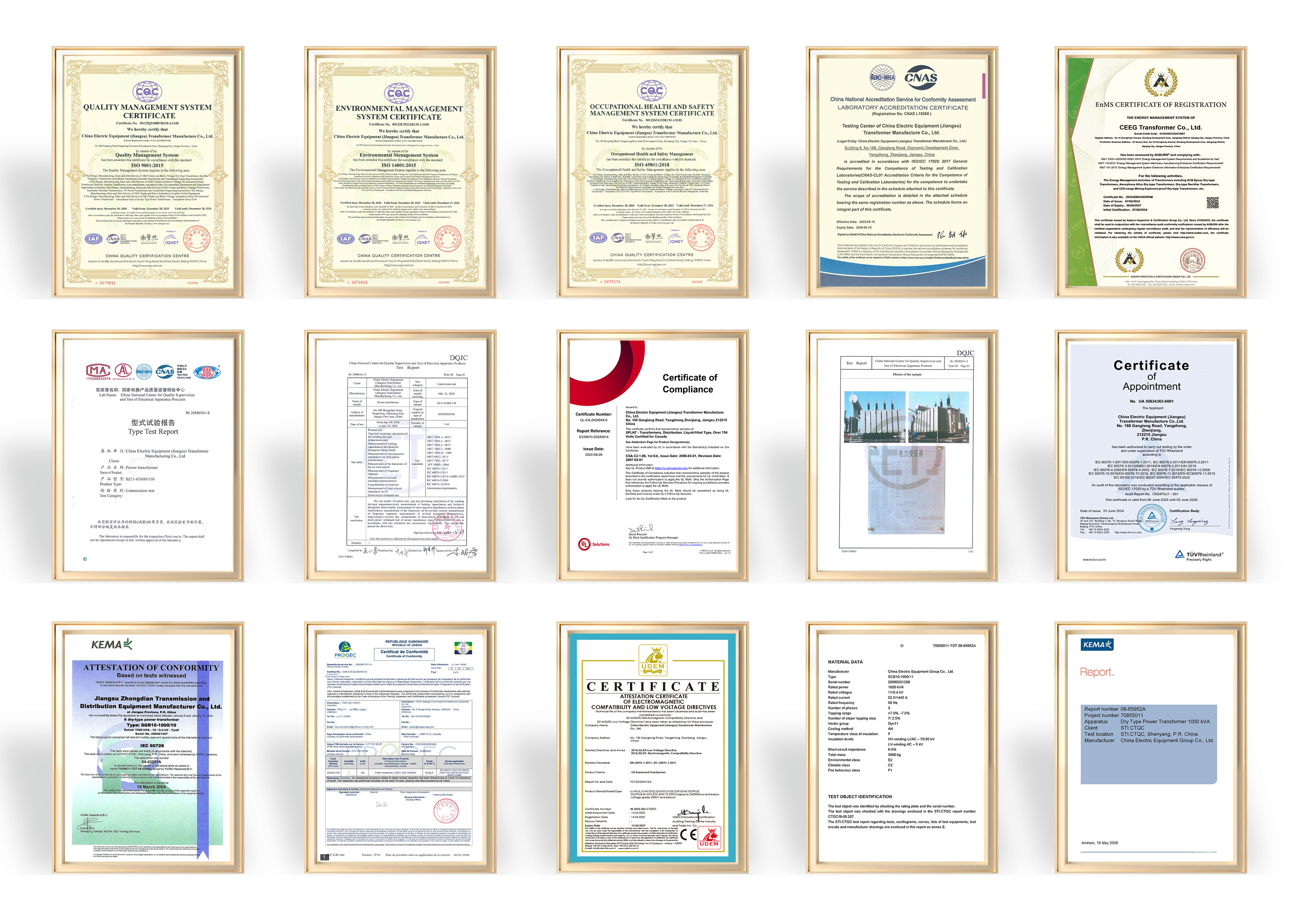

The company has 2 CNAS laboratories and 1 TÜV Rheinland witness laboratory. All products undergo strict testing and inspection by relevant standards and customized requirements of customers before leaving the factory.

.jpg)

PARAMETERS

.png)