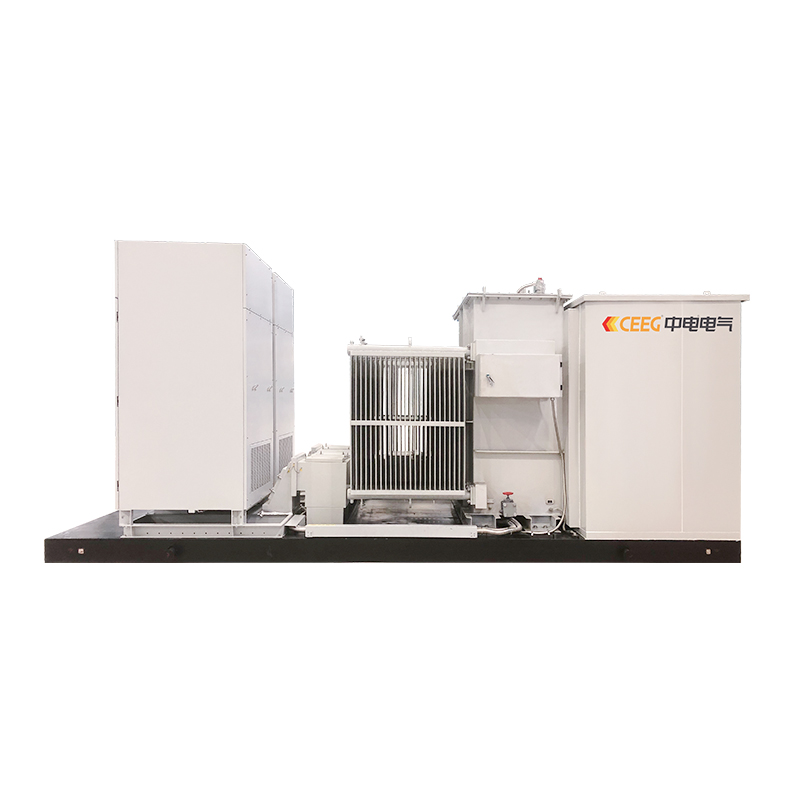

PRODUCT OVERVIEWS

The hydrogen energy dedicated dry-type rectifier transformer produced by China Electric can effectively improve the efficiency of water electrolysis, reduce comprehensive power consumption, and enhance operational reliability. All performance indicators meet or exceed the latest national standards.

Performance Characteristics

Safe and reliable

The transformer is made of non-toxic flame-retardant epoxy resin infusion, with high mechanical strength, flame retardancy, fire resistance, and no pollution.

Easy installation

Dry-type rectifier transformer can be put into operation as soon as the whole machine is in place, which is convenient and efficient.

High overload

The insulation heat resistance level of the transformer is H level, with a heat resistance temperature of 180 ℃ and a maximum overload capacity of 200%.

Saving investment

Dry-type rectifier transformers can be installed together with rectifiers and other electrical equipment, without the need for a separate distribution room, saving space and reducing investment.

Manufacturing Process

Reliability of Insulation Technology

From the initial two-dimensional electric field simulation, three-dimensional electric field measurement, and impulse characteristic measurement, to the later theoretical analysis and simulation tests on the characteristics of the transformer's main insulation, longitudinal insulation, end insulation, lead insulation, and coil under lightning impulse voltage, the reliability of the insulation is ensured.

Calculation of leakage magnetic field and reduction of stray losses

Research is conducted specifically on the calculation and measurement of transformer leakage magnetic field, shielding structure of leakage magnetic field, calculation of transformer dynamic and thermal stability, and improvement of transformer dynamic and thermal stability capabilities to ensure the calculation of leakage inductance field and reduce stray losses.

Accurate analysis of the coil temperature field

Our company has developed a calculation program for the temperature field of the coil, which accurately calculates the temperature distribution of the coil and the temperature rise of the hot spot by calculating the loss distribution and flow velocity field cooling condition of the coil, to take measures.

Reduce the local discharge of transformers

The electric field strength of each part has been analyzed and strictly controlled during the design phase.

.jpg)

PARAMETERS

.png)