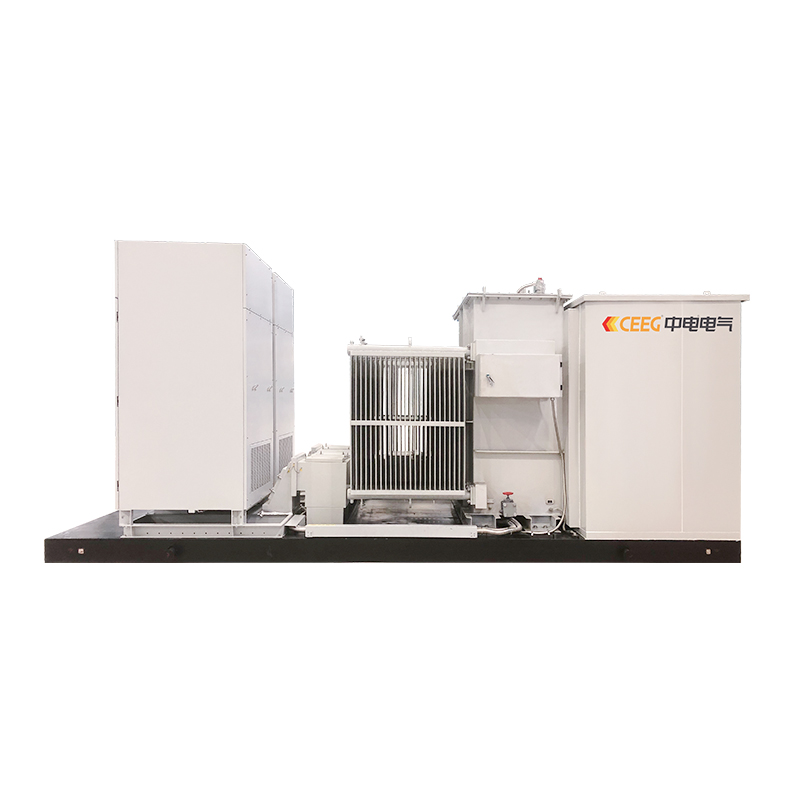

PRODUCT OVERVIEWS

The general dry-type transformer for mining is mainly used in iron ore, copper ore, gold ore, aluminum ore, stone ore, rock ore, metal and non-metal mines, as well as roads, railways, tunnels, etc.

Earthquake-resistant and corrosion-proof

The enclosure is made of high-quality structural steel and cold-rolled steel plates welded into shape, with five-layer paint coating, providing strong earthquake resistance and corrosion protection.

Safe and reliable

Flame-retardant, fireproof, moisture-proof, with natural ventilation and automatic control fan devices to effectively regulate temperature through forced cold air.

Environmentally friendly and energy-saving

No pollution, low loss, low partial discharge, low noise, and strong heat dissipation capabilities.

Excellent performance

Performance parameters exceed national standards, ensuring quality and reliability.

MANUFACTURER PROCESS:

3D Design

CEEG's "3D + Parametric" design software enables automated design, cost optimization, simulation, and emulation, fully considering national and industry standards and ensuring the advanced design of products.

High-Voltage Winding

The high-voltage winding conductors are made of high-quality materials, with reinforcement fillers using long and short cut glass fiber mats. They are cast under vacuum using the world-class HEDRICH vacuum casting system, achieving a partial discharge level of less than 5 pC.

Low-Voltage Winding

The low-voltage windings are made with high-quality pin conductors, wound on automatic box winding machines. These machines utilize wire hydraulic energy-saving tension curling device," with ±0.5mm high-precision detection and advanced hydrogen arc welding technology.

Core

The core adopts a multi-stage stepping process with through-core positioning structures, ensuring no lateral or longitudinal displacement under various operating conditions.

Testing and Inspection Technology

All products undergo rigorous testing before delivery according to relevant standards and customer-specific requirements, including partial discharge testing, lightning impulse withstand testing, noise testing, and other mandatory inspections.

.png)

PARAMETERS

.png)