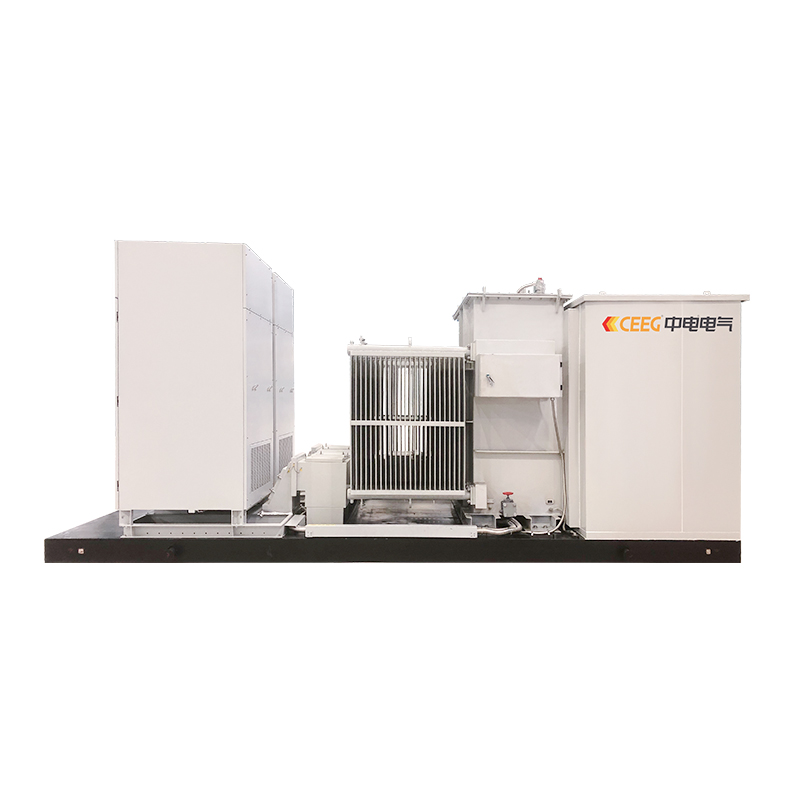

PRODUCT OVERVIEWS

CEEC's hydrogen production rectifier transformers are widely applicable to water electrolysis hydrogen production equipment in the hydrogen energy industry chain, especially in fields such as new energy hydrogen production bases, industrial park hydrogen supply, transportation energy, and energy storage facilities.

Performance Features

High overload capacity

The transformer has an insulation heat resistance class of H, with a heat resistance temperature of 180℃. The maximum overload capacity reaches 200%.

Low noise

Aiming at the principle of noise generation, unique noise reduction measures are adopted for different components. The self-cooling noise level is lower than the national standard, reduced by 3 - 5 decibels compared with the national standard.

Safety and reliability

The transformer is made of non-toxic and flame-retardant epoxy resin by pouring. It has high mechanical strength, is flame-retardant, fireproof, and pollution-free.

Authoritative certification

It has passed the authoritative certification of the National Electrical Product Quality Supervision and Inspection Center.

Manufacturing Process

Multi-pulse rectification technology and harmonic suppression technology

It took the lead in successfully researching, developing, and launching 96-pulse (48-pulse for a single unit) oil-immersed hydrogen energy rectifier transformers in China, providing solid technical support for the efficient and stable development of the hydrogen energy industry.

High-temperature resistant hybrid insulation system

Using temperature field analysis software to determine the temperature distribution of coil hot spots, and reasonably selecting insulating materials with different temperature resistance levels, so that the service life of each component in the overall insulation system of the transformer exceeds 30 years.

Fully automatic lamination

Robot-based automatic lamination, adopting a full 45-degree inclined 7-level stepped joint structure, improves the efficiency and quality of transformer lamination.

Testing and detection technology

The company has 2 CNAS laboratories and 1 TÜV Rheinland witness laboratory. All products undergo rigorous testing and inspection against relevant standards and customer-specific requirements before being shipped from the factory.

.png)

PARAMETERS

.png)