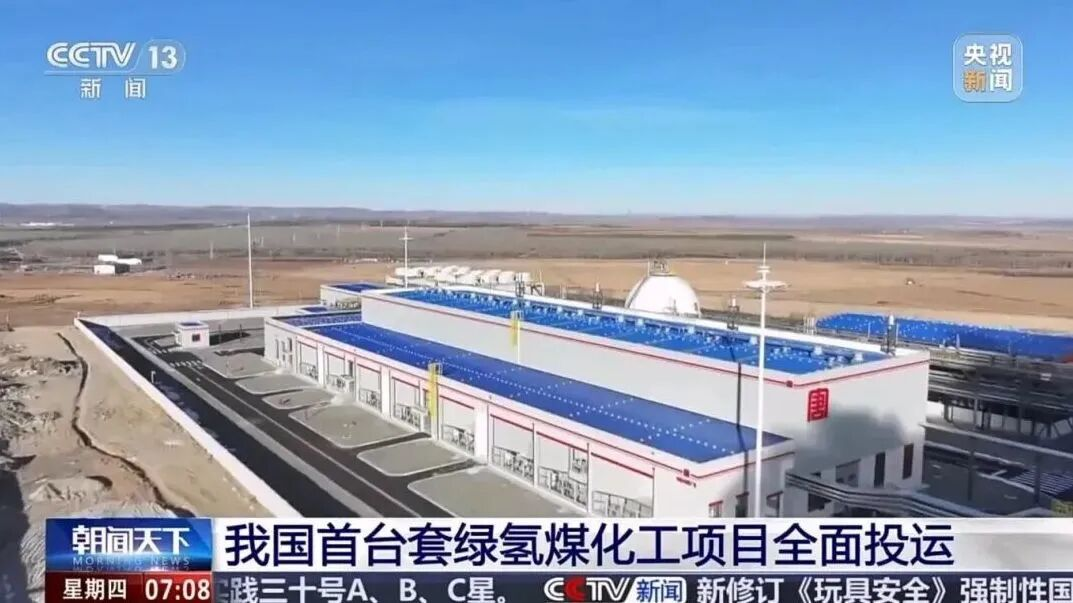

Recently, the milestone moment of the China Datang Duolun 150 MW wind–solar–storage–hydrogen integrated demonstration project entering full market-based operation once again received focused coverage from CCTV and other national authoritative media.

This is not only a major practical achievement in the complex “wind–solar–storage” hydrogen production scenario, but also the first domestic demonstration project for large-scale green hydrogen coupling with the coal-chemical industry, opening a new pathway for deep decarbonization in energy-intensive sectors.

一、Renewed Spotlight: National Demonstration Under CCTV’s Lens

Following its contribution to the Jilin Da’an project, which appeared on Xinwen Lianbo, CEEG once again receives attention from national-level media. CCTV’s coverage serves as a vivid endorsement of the strategic pathway: “green power produces green hydrogen, and green hydrogen reduces carbon emissions.”

As the camera shifts from the spectacular wind-solar-storage base to the stably operating power system, it conveys a clear message: China now possesses mature engineering capabilities and reliable domestically manufactured core equipment to address the challenge of producing hydrogen efficiently and steadily from fluctuating renewable energy sources.

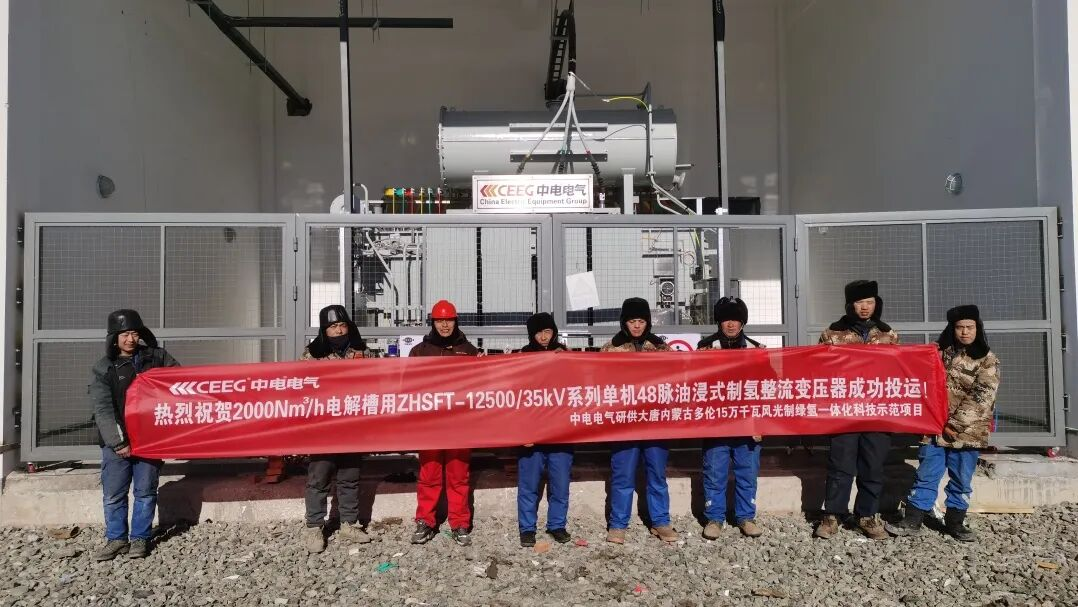

二、 Core Strength: CEEG’s Role as the “Stabilizer”

In the complex system of wind–solar–storage hydrogen production, the key technical challenge lies in converting intermittent and fluctuating wind and solar power into a stable, smooth current—similar to that of a precision DC power supply—required by electrolyzers. This is the critical bottleneck that determines the success of the entire project.

This is exactly the core mission carried by the five ZHSFT-12500/35kV single-unit 48-pulse rectifier transformers supplied by CEEG.

Unlike conventional transformers, this “heart” equipment—purpose-built for large-scale water electrolysis hydrogen production—features a top-level “single-unit 48-pulse” design. This means it can generate DC power with extremely low harmonics and a very small ripple factor right from the source.

Facing the random fluctuations of wind and solar power, it functions like a powerful “power stabilizer,” ensuring a continuous and high-quality power supply for downstream electrolyzers with an annual production capacity of several thousand cubic meters, thus guaranteeing hydrogen production efficiency and long-term safe operation of the equipment.

三、North–South Validation: Building a Foundation of Top-Tier Industry Trust

From Da’an in Jilin to Duolun in Inner Mongolia, CEEG’s solutions have supported the successful commissioning of two major national benchmark projects within a short period of time.

The Da’an project verified the extreme reliability of the equipment in a pure renewable-energy base, while the Duolun project demonstrated its outstanding adaptability under complex conditions involving industrial load coupling.

Through this “dual-star validation,” CEEG has ascended to become a “core power system solutions partner” that has undergone the most rigorous tests in the wave of green hydrogen industrialization.

This is not only a snapshot of the ongoing energy transition, but also powerful evidence that China’s high-end equipment—backed by hard-core technology—is steadily supporting a greener future.

With the consecutive successful commissioning of these two north–south benchmark projects, CEEG is now deeply involved in and actively advancing the historic progress of China’s green hydrogen industrialization with its proven, hard-core capabilities. We will continue to contribute our professional value with reliable “heart” strength to support the realization of the national “dual-carbon” goals.