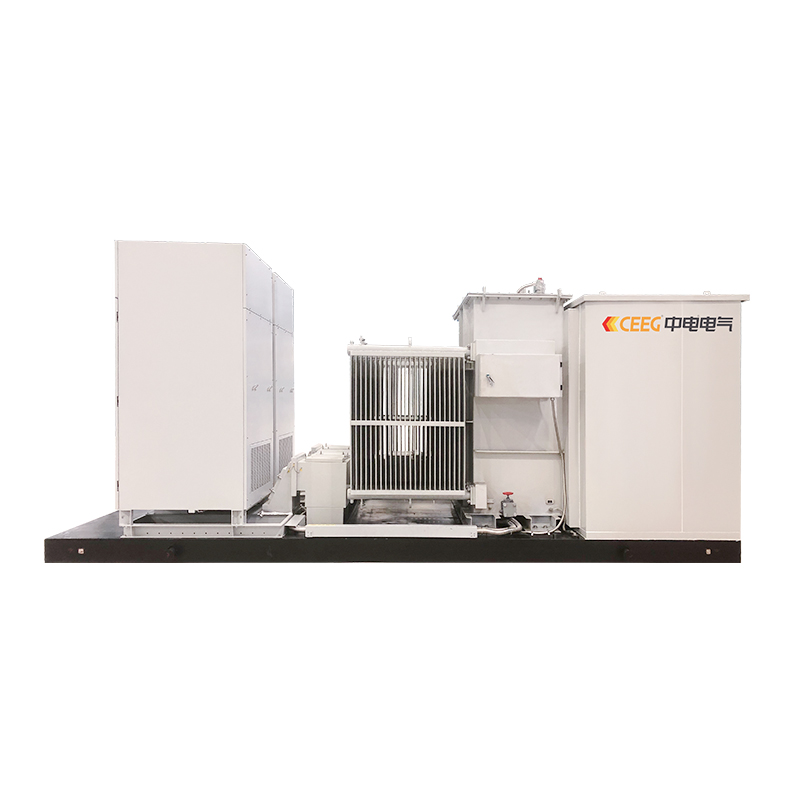

PRODUCT OVERVIEWS

Amorphous alloy dry-type transformers utilize advanced amorphous alloy materials, effectively reducing no-load losses by up to 60%–80%. CEEG's amorphous alloy transformers are environmentally friendly and energy-efficient, with excellent electrical performance, making them the ideal choice for major data centers!

Advanced Technology:

Unique patented semi-enclosed three-phase three-column design, compact size, lightweight, resistant to high-order harmonics, with independent production lines and manufacturing processes for amorphous alloy cores.

High Efficiency and Energy Saving:

Uses amorphous alloy strip material with high mechanical strength, reducing no-load losses by 60%–80% and no-load current by 70%–85%.

Nomex® Insulation Paper:

Maintains effective performance for over 10 years at continuous exposure to 220°C; UL material temperature of 200°C; qualifies for a 3,500V withstand voltage test.

Durability:

Strong short-circuit resistance, long service life, dustproof, moisture-proof, salt fog resistant, with excellent "three-proof" capabilities and no cracking phenomena.

Manufacturing Process:

CEEG's "3D + Parametric" design software enables automated design, cost optimization, simulation, and emulation, fully considering national and industry standards and ensuring the advanced design of products.

Low-Voltage Foil Winding Coil

Made with high-quality copper foil and H-grade insulating materials wound onto a molded insulating cylinder. Layer insulation uses Nomex® paper, and vacuum-pressure impregnation (VPI) ensures a solid, integrated structure. The top and bottom ends are sealed with resin. Lead copper bars and copper foils are welded using TIG (argon arc) welding with specialized equipment.

High-Voltage Winding Coil:

A multi-layer segmented cylindrical structure with multiple longitudinal air ducts is adopted, offering strong resistance to heat and mechanical shock, as well as excellent impulse withstand capability. Flat copper wire wrapped with Nomex® paper is used as the conductor, Nomex® paper is used for interlayer insulation, and H-class materials are used for end insulation.

Core:

The core features a simple structure with 70%-80% lower iron losses compared to conventional products. Its unique manufacturing process provides high mechanical strength, ensuring that its characteristics and structure are unaffected by transportation or vibrations.

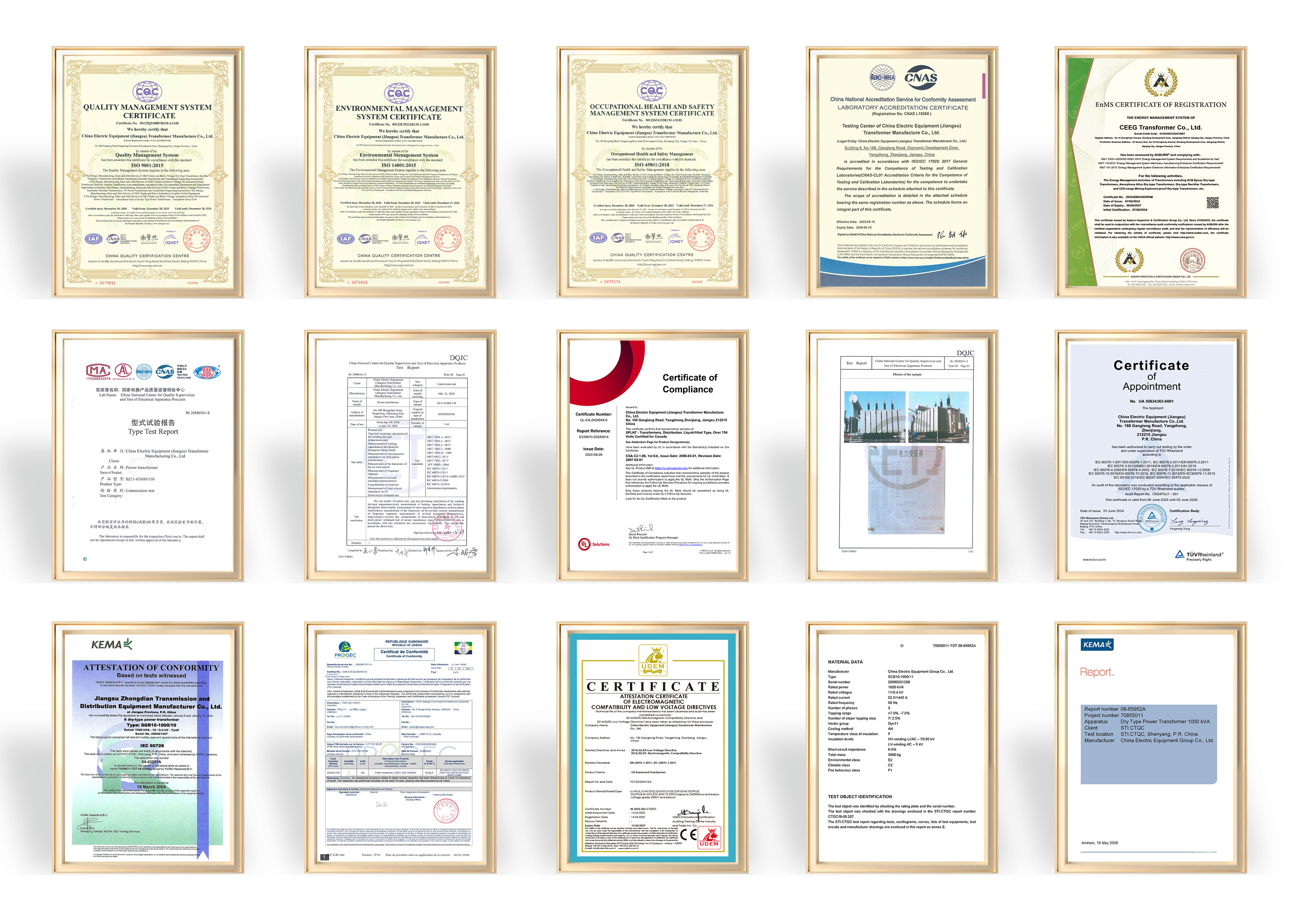

Testing and Inspection Technology

All products undergo rigorous testing before delivery according to relevant standards and customer-specific requirements, including partial discharge testing, lightning impulse withstand testing, noise testing, and other mandatory inspections.

.jpg)

PARAMETERS

.png)