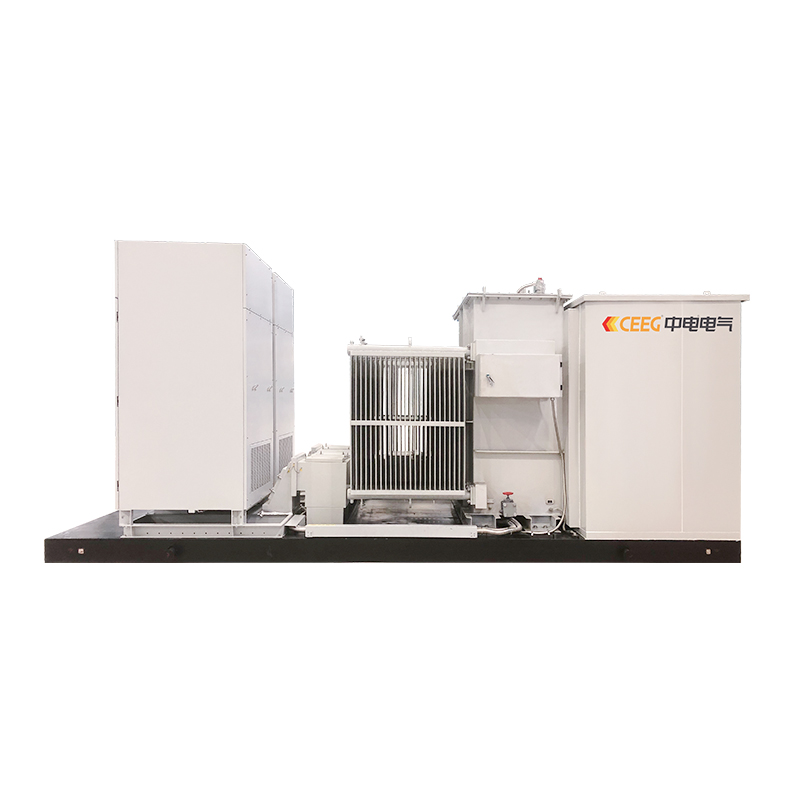

PRODUCT OVERVIEWS

Performance Features

High Safety

The S(G)B series transformer core contains no combustible resin. It is non-combustion-supporting during operation and is flame-retardant. It exhibits minimal partial discharge during operation and will never develop cracks. Its safety performance makes it particularly suitable for locations with stringent fire protection requirements and high population density.

High Reliability

Both high- and low-voltage windings adopt Nomex® paper insulation, impregnated multiple times with H-class, solvent-free varnish using VPI (Vacuum Pressure Impregnation) equipment, followed by multiple cycles of high-temperature curing. The product is rated Class H (180 °C), with primary insulation materials meeting Class C (220 °C), ensuring a large overload margin and excellent short-circuit withstand capability.

Energy Saving & Environmentally Friendly

At the end of its service life, copper, steel, and other materials are easily recyclable. Nomex® insulation paper does not release toxic substances when burned, and other insulation materials are degradable and non-polluting to the environment.

“Three-Proof” Protection

Moisture-proof, salt-fog-proof, and corrosion-resistant, with strong weatherability and a long service life.

Manufacturing Process:

CEEG's "3D + Parametric" design software enables automated design, cost optimization, simulation, and emulation, fully considering national and industry standards and ensuring the advanced design of products.

Low-Voltage Foil Winding Coil

Made with high-quality copper foil and H-grade insulating materials wound onto a molded insulating cylinder. Layer insulation uses Nomex® paper, and vacuum-pressure impregnation (VPI) ensures a solid, integrated structure. The top and bottom ends are sealed with resin. Lead copper bars and copper foils are welded using TIG (argon arc) welding with specialized equipment.

High-Voltage Winding Coil:

A multi-layer segmented cylindrical structure with multiple longitudinal air ducts is adopted, offering strong resistance to heat and mechanical shock, as well as excellent impulse withstand capability. Flat copper wire wrapped with Nomex® paper is used as the conductor, Nomex® paper is used for interlayer insulation, and H-class materials are used for end insulation.

Core:

The core features a simple structure with 70%-80% lower iron losses compared to conventional products. Its unique manufacturing process provides high mechanical strength, ensuring that its characteristics and structure are unaffected by transportation or vibrations.

Testing and Inspection Technology

All products undergo rigorous testing before delivery according to relevant standards and customer-specific requirements, including partial discharge testing, lightning impulse withstand testing, noise testing, and other mandatory inspections.

.jpg)

PARAMETERS

.png)