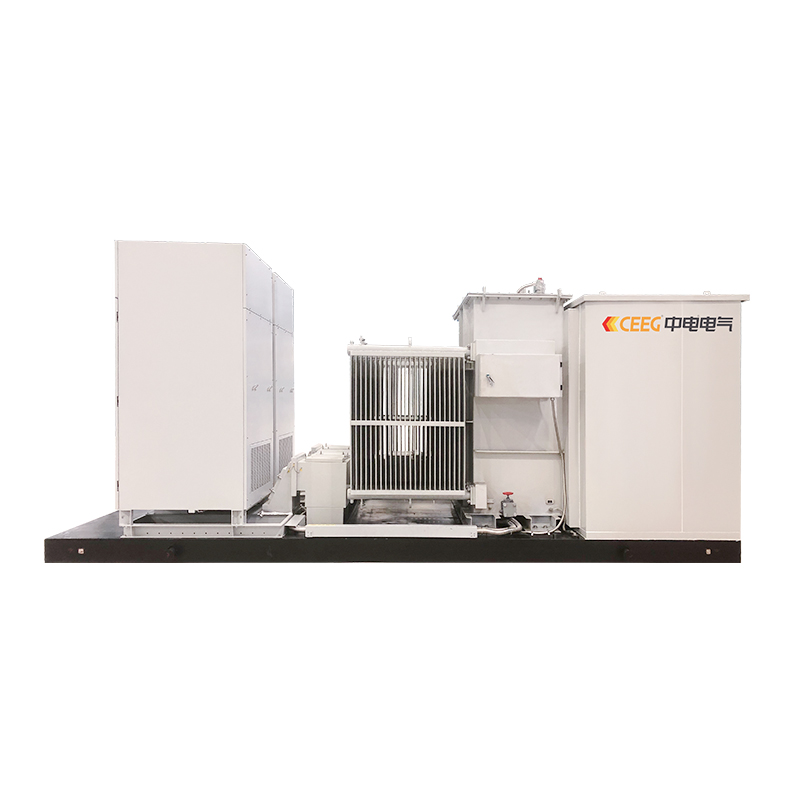

PRODUCT OVERVIEWS

The SRN-M series high-temperature resistant liquid-immersed transformers are applied in industries such as steel, coal, chemical engineering, papermaking, and metallurgy. With their unique high-temperature resistant design, they ensure the stability and safety of power transmission.

Performance Features

Strong overload capacity

With DuPont Nomex® paper as the core, seven-level temperature control technology is adopted.

Wide application range

It can providea safe and reliable power supply in industries with high ambient temperatures or long-term high-load operation.

High stability

It has good oxidation resistance and a slow aging rate. Its mechanical and electrical properties are more stable, and it has a long service life.

Energy conservation and environmental protection

After the service life, the materials can be recycled and reused without causing pollution.

Manufacturing Process

3D design

CEEC's "3D + parameterization" design software can realize automatic design, cost optimization, simulation, and emulation. It fully considers national and industry standard requirements to ensure the advanced nature of the product in design.

High-temperature resistant hybrid insulation system

Using temperature field analysis software to determine the temperature distribution of coil hot spots, and reasonably selecting insulating materials with different temperature resistance levels, so that the service life of each component in the overall insulation system of the transformer exceeds 30 years.

Fully automatic lamination

Robot-based automatic lamination, adopting a full 45-degree inclined 7-level stepped joint structure, improves the efficiency and quality of transformer lamination.

Testing and detection technology

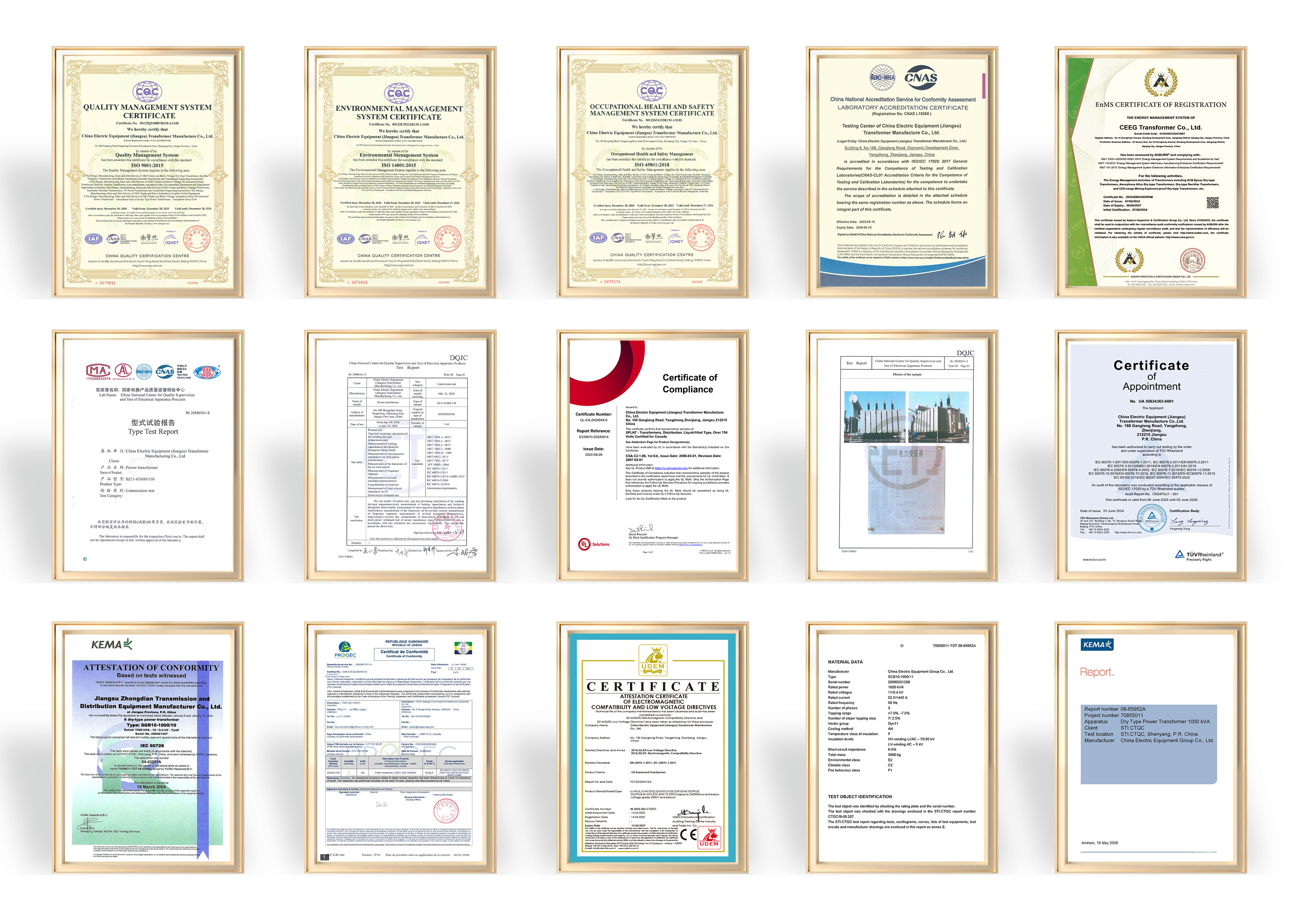

The company has 2 CNAS laboratories and 1 TÜV Rheinland witness laboratory. All products undergo rigorous testing and inspection against relevant standards and customer-specific requirements before being shipped from the factory.

PARAMETERS

.png)